- Product

Overview - Photo

Gallery - Video

gallery - Product

Specifications - Request

a quote

Reliable and efficient design of Atlas bitumen drum decanters are ideal for melting bitumen at sites where bitumen is not available in liquid form or where bitumen is only available in the form of drums. These machines are developed keeping in mind the practical aspects of melting asphalt at construction site with less or no facility and also for places which are very remote. It will help you get tension free as far as melting, storage and reheating of bitumen packed in drums is considered.

If you already have an asphalt plant, and are getting bitumen in drums, you can use the bitumen decanter to melt bitumen and store liquid bitumen in the space provided in the machine itself. This liquid bitumen can be transferred to your bitumen tanks in the asphalt plant as the integration is very easy. You can even transfer the liquid bitumen to bitumen tanks to take away to another site or to bitumen distributors. The best part of this equipment is that it can be easily integrated as per your requirement.

Heating is by use of thermic fluid system with automatic burner. This method is indirect heating. This method is best because it heats bitumen efficiently and also prevents ageing of bitumen if in case you want to reheat bitumen many times.

Main components include:

- Main body

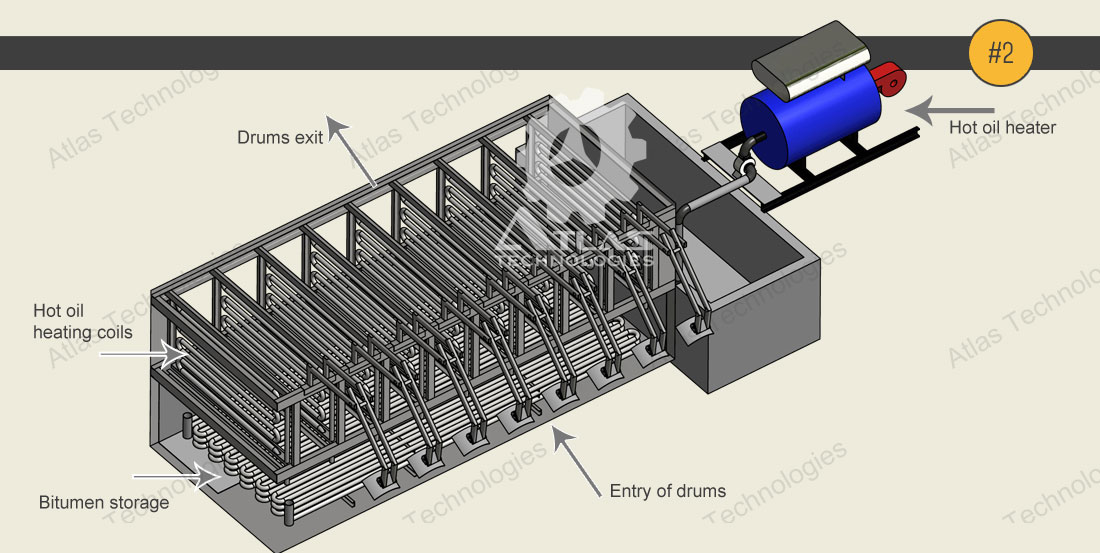

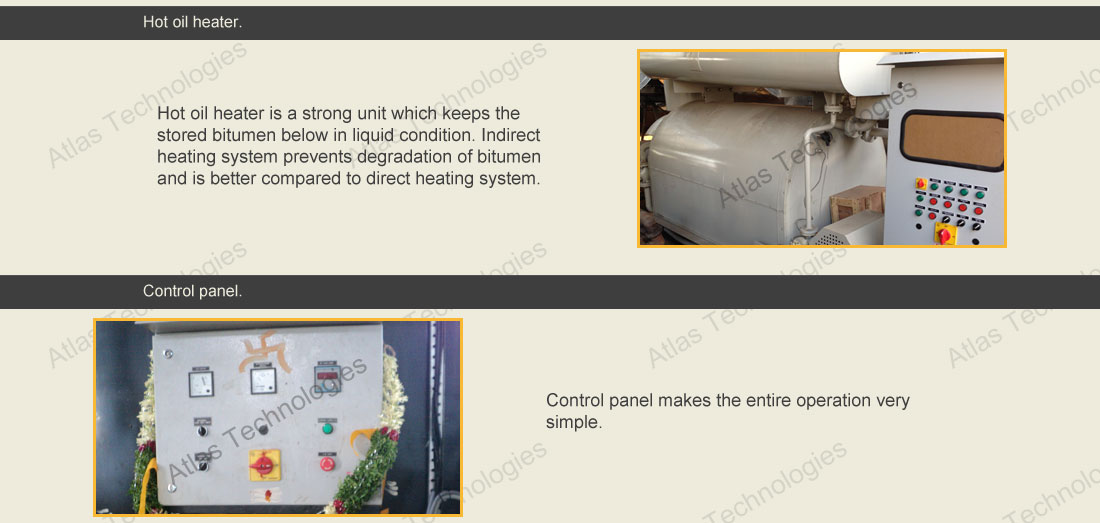

- Hot oil heater with heat transfer coils that contain and carry hot oil from the boiler unit to the asphalt melting equipment for heating.

- Fuel tank that provide fuel to the burner of themic oil heater.

- Asphalt pump for pumping bitumen to the awaiting tanks.

- Control panel unit.

Features:

- Easy to use machine.

- Easy to assemble and disassemble.

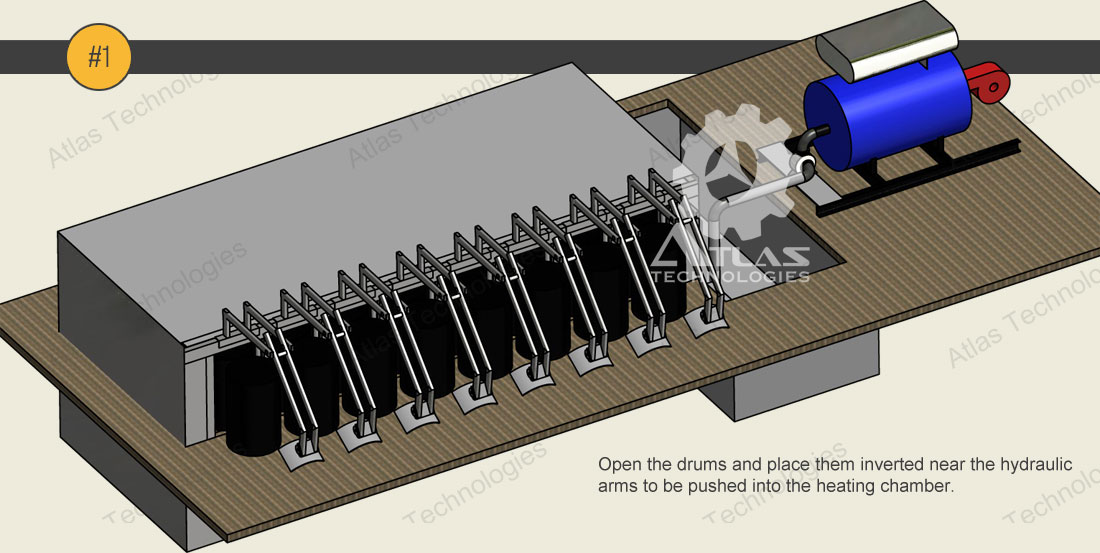

- Effortless loading of drums by hydraulic arms.

- High reliability factor as the burner and hot oil system is tried and tested in our asphalt batch plants.

- Can be applied and integrated in any system and can be used to fill any awaiting tank / vehicle.

- Main body where heating takes place is fully insulated by glasswool from all the sides.

- Upper part is melting zone and the lower part is for sufficient storage of liquid bitumen.

- Bitumen tanks can be supplied and integrated with the same for additional storage of bitumen.

- Easy to use equipment even with less labour. Works fine even if the drums are out of shape.

The basic working of the bitumen melting machine:

Open the drums and place them inverted near the hydraulic arms to be pushed into the heating chamber.

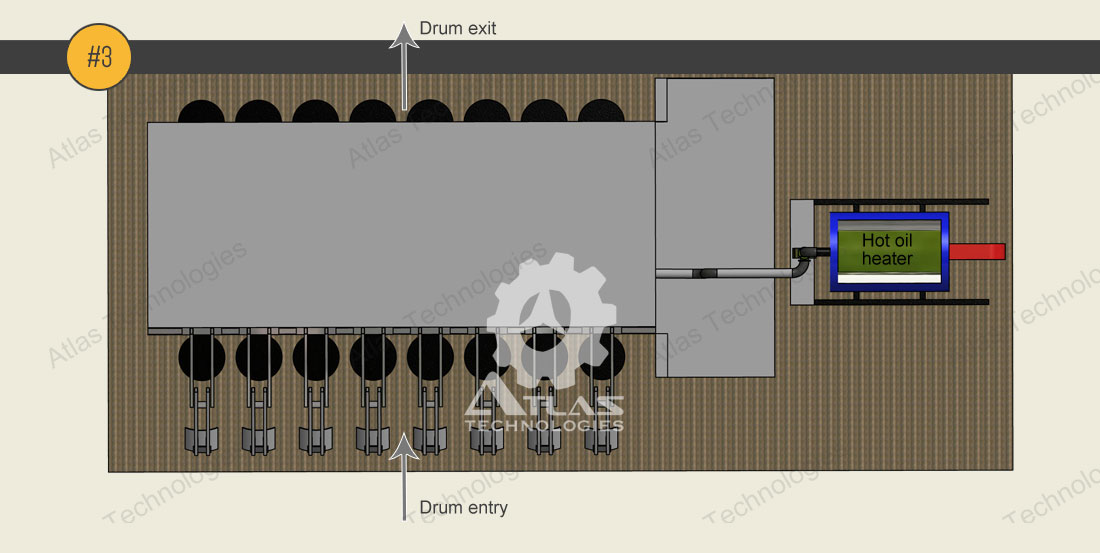

The heating chamber consists of coils that run from below the machine to near the drums. These coils run hot oil from them (about 200 degree Celsius) to heat the liquid bitumen below and also the drums in the upper part of the chamber.

The drums will be pushed to the other end of the drum decanting unit in a continuous manner as new drums continue to get inside the melter by the hydraulic arms. As they get pushed to the other end, bitumen melts and is collected in the chamber below. Here the drums are placed on rails and the other end is the rear door for exit of empty drums.

The main chamber is fully insulated by glasswool from all the sides to prevent heat loss. The entry and exit doors are also made for easy entry and exit of bitumen drums.

By the time the drums come out from the other end, bitumen is fully emptied and collected. The control panel of drummed bitumen melting plant is easy to use and loading of drums is most easy in this design.