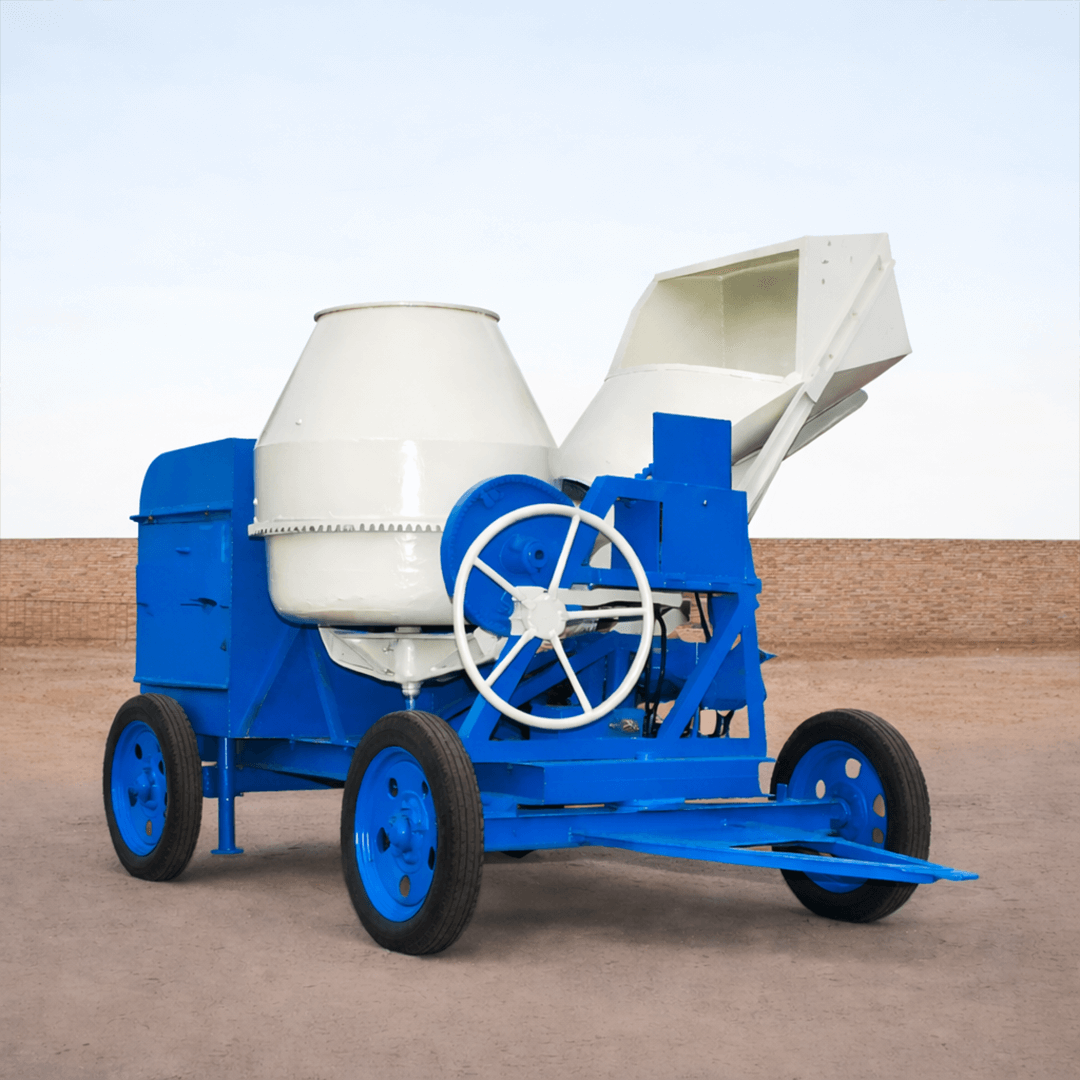

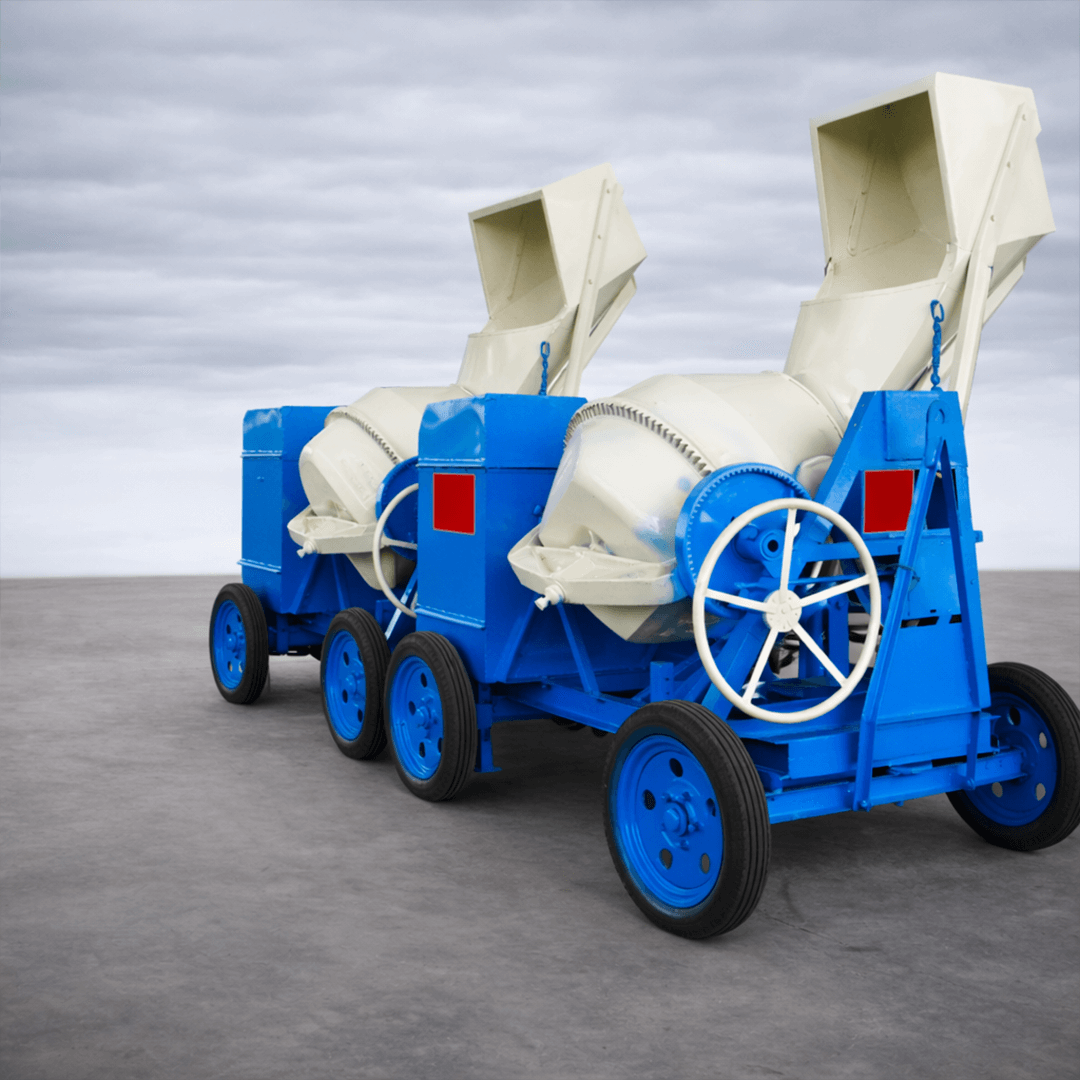

10/7 Concrete Mixer With Mechanical Hopper (Diesel / Electric)

Capacity: 10/7 Cubic Feet (~0.2 m³) | Best for: Projects Requiring Reduced Manual Handling

The Atlas 10/7 Concrete Mixer – With Mechanical Hopper is a durable, semi-automatic mixer designed to reduce manual labour during concrete feeding. Available in both diesel and electric variants, it combines dependable mixing with mechanical lifting, ensuring smooth, efficient batch loading for consistent output on mid-scale construction sites....

Read More

10/7 Concrete Mixer (Mechanical Hopper): Simplified Loading, Consistent Mixing

Key Features & Benefits

Built for Productivity, Ease of Use, and Site Flexibility

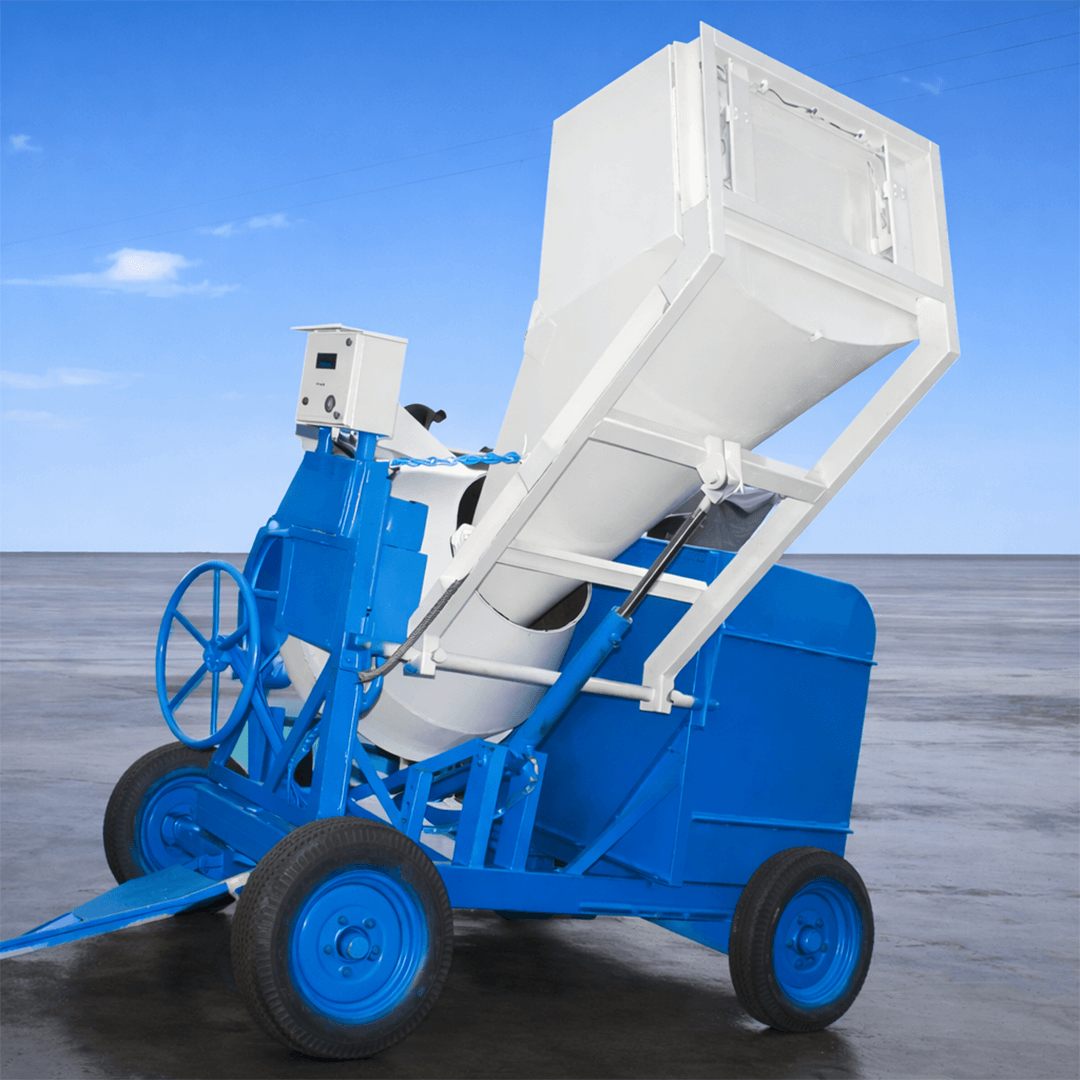

Mechanical Hopper Lift System

Reduces manual labour by lifting and feeding aggregates directly into the drum, improving batching efficiency.

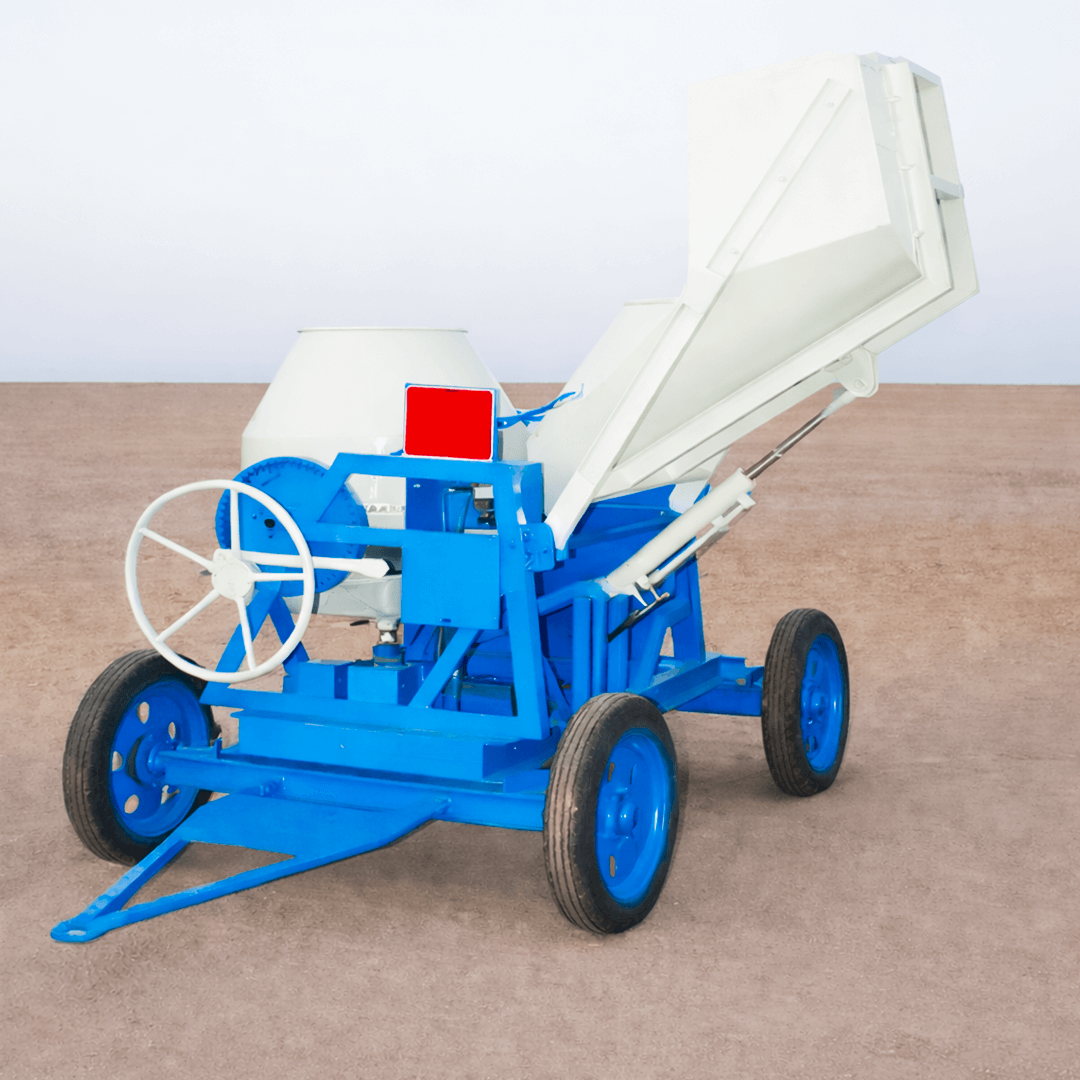

Dual Power Options (Diesel / Electric)

Offers flexibility for both on-grid and remote sites, ensuring uninterrupted operation under all conditions.

10/7 Cubic Feet Mixing Capacity

Produces approximately 0.2 m³ per batch, ideal for building foundations, pavements, and site concreting.

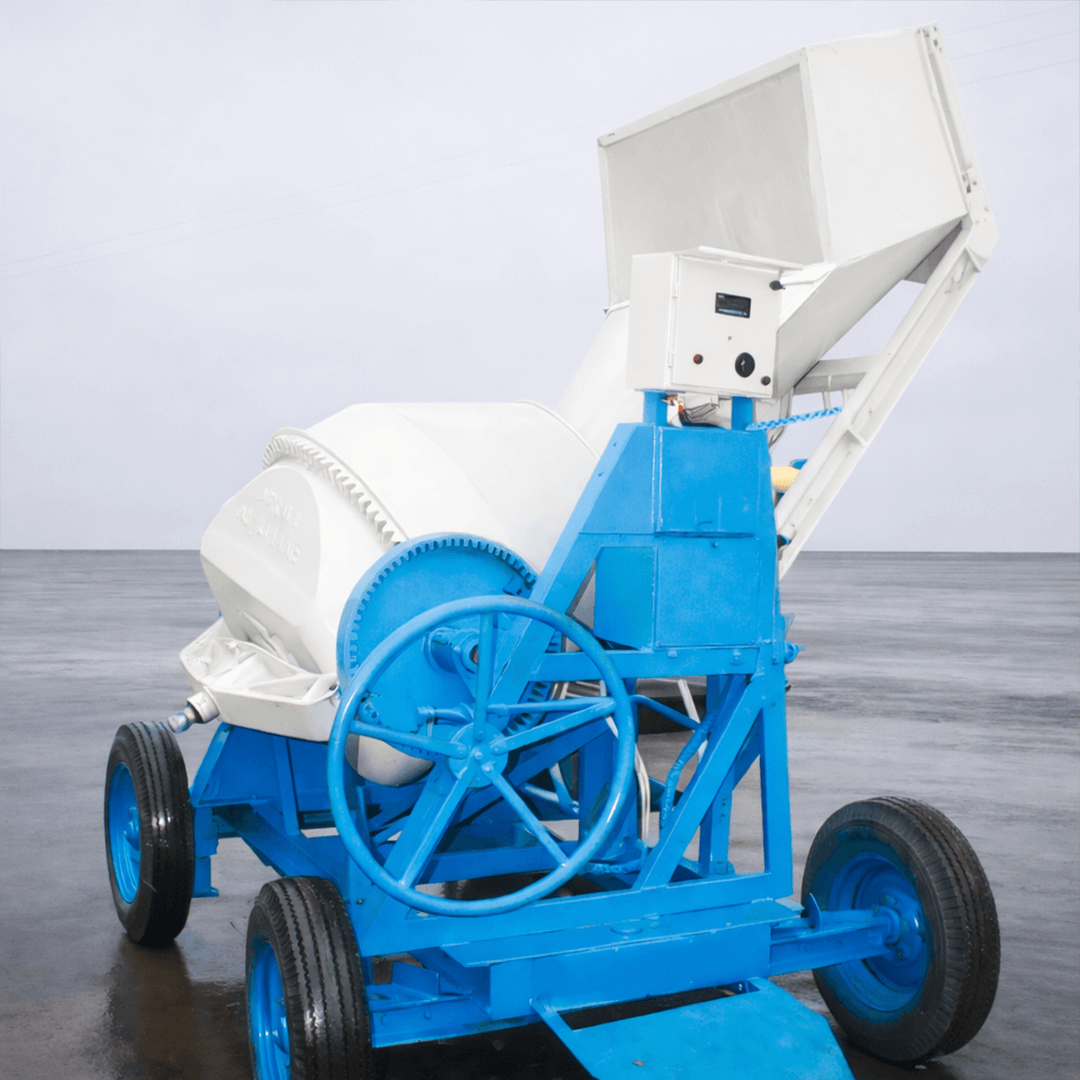

Heavy-Duty Mixing Drum

Cast iron drum with replaceable fins ensures long life and uniform concrete consistency.

Why Choose the Diesel Model Without a Hopper

This model is the ideal choice for contractors seeking faster batching without the complexity of hydraulic systems.

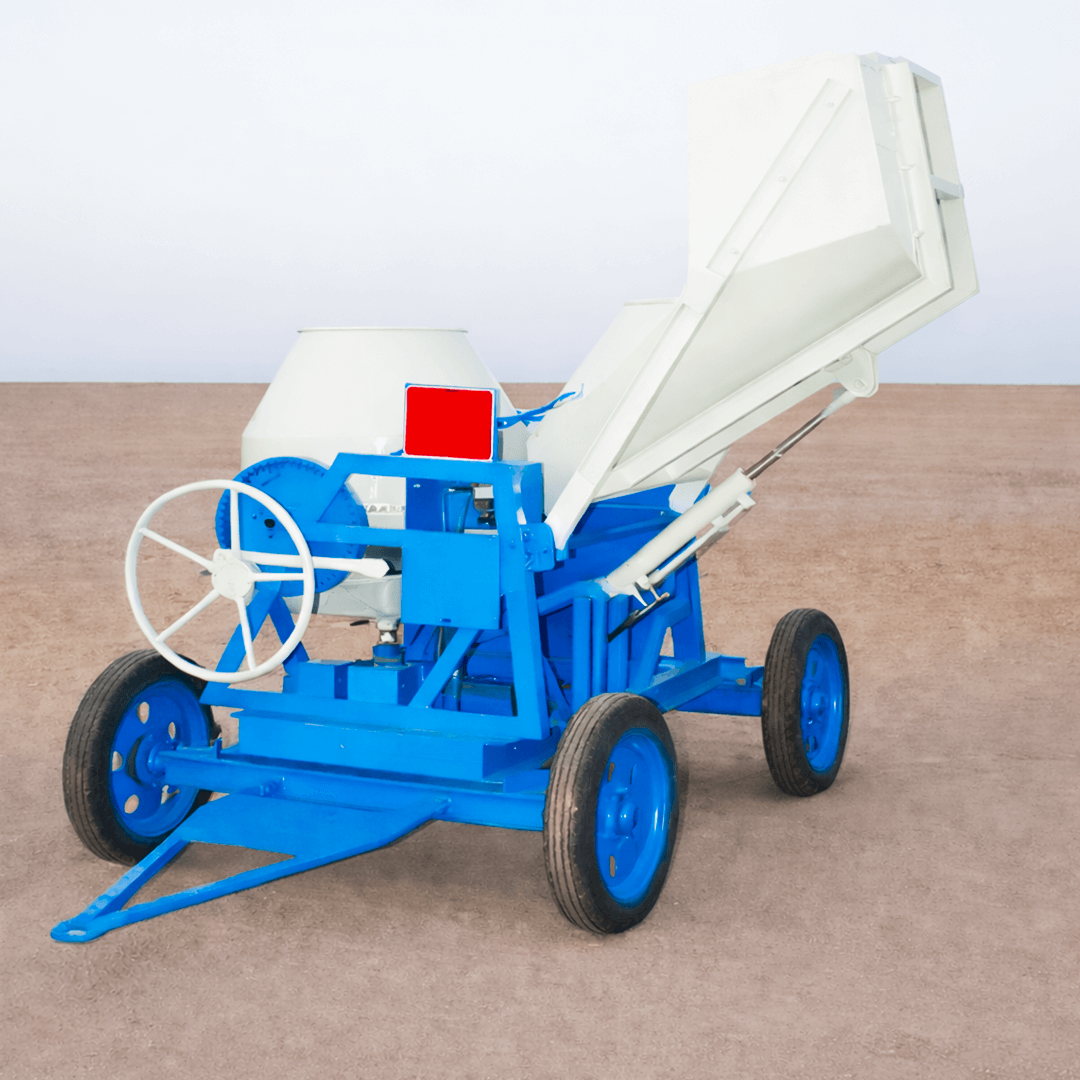

Perfect for Medium-Sized Construction

Efficiently handles multiple daily batches with quick load cycles and minimal operator fatigue.

Labour-Saving Design

Mechanical loading significantly reduces manual shovelling, increasing productivity on site.

Flexible Power Configuration

Choose between diesel (mobility and independence) or electric (low-noise, low-emission) power.

Built for Long-Term Use

Strong steel chassis and drum ensure reliable operation in a rugged site environment.

Low Maintenance System

Simple mechanical linkage with easy lubrication and quick part replacement.

Components Breakdown

The 10/7 Mechanical Hopper Mixer is engineered for efficient feeding, durable operation, and easy upkeep.

- • Diesel engine (6 HP) or electric motor (7.5 hp) with belt-driven transmission.

- • Energy-efficient system with accessible maintenance points.

Smart Design, Seamless Operation

Browse our range of products designed for exceptional performance and reliability.

CONNECT WITH US

Ready to Build? Let’s Talk!

Whether you’re expanding existing facilities or starting new projects, we’re here to help you achieve optimal results. Complete the form, and our engineers will provide a customized solution within 24 hours.

Frequently asked questions.

1. How does the mechanical hopper work?

+The hopper uses a chain or gear-driven lifting mechanism to load aggregates and cement into the drum automatically.